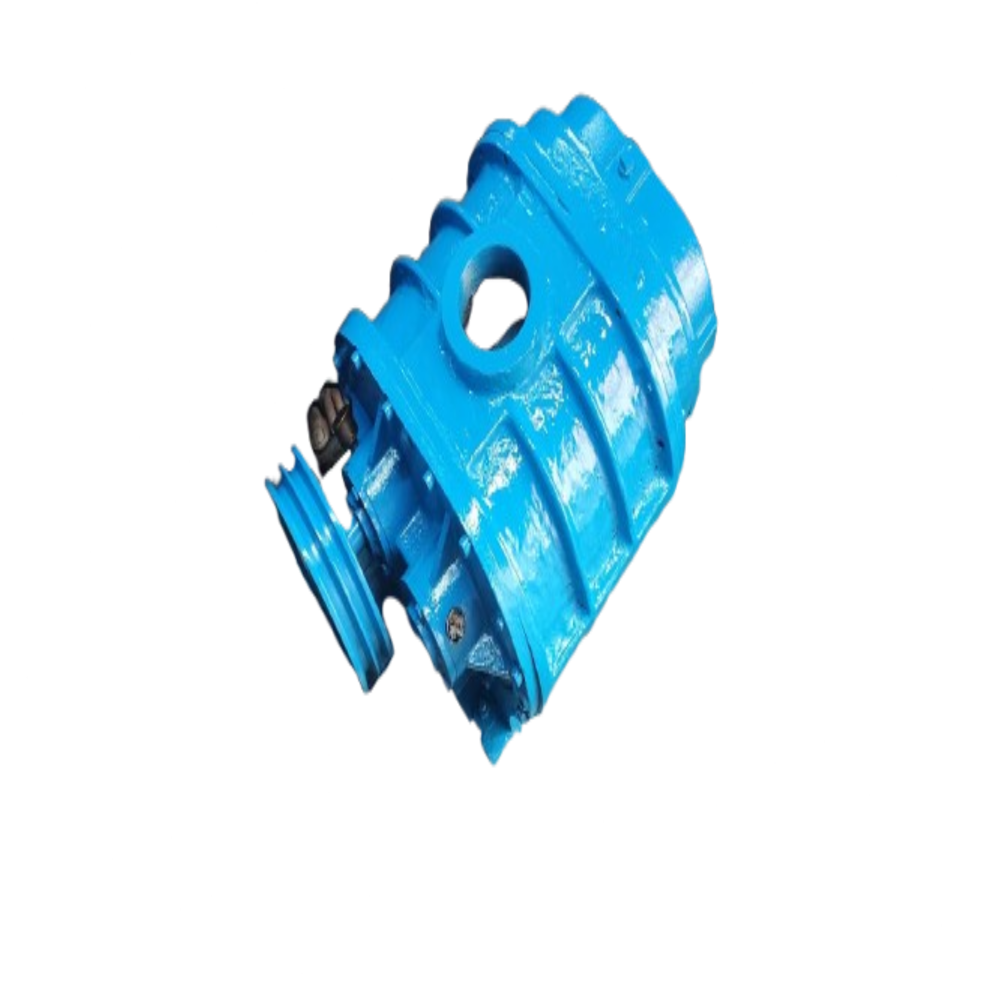

Magnet Drive Filter Unit

Magnet Drive Filter Unit Specification

- Shelf Life

- Long Life

- Temperature Range

- Up to 70C

- Packaging Type

- Wooden Box

- Tank Capacity

- Varies (Customizable)

- Equipment Type

- Industrial Filtration Equipment

- Grade Standard

- Industrial Grade

- Equipment Type

- Magnet Drive Filter Unit

- Dimension (L*W*H)

- As per requirement

About Magnet Drive Filter Unit

We have carved a strong niche for ourselves in the domestic and overseas markets by offering an innovative range of Magnet Drive Filter Unit. These units are suitable for filtering plating, acid and alkaline solutions. We employ ultra modern techniques and quality approved materials to manufacture Magnet Drive Filter Unit, in compliance with international quality standards. Furthermore, to attain maximum satisfaction of the patron, our range is delivered to their destination in stipulated period of time.

Features:

- Compact design

- Less powder consumption

- Reliable operation

Customizable Industrial Filtration Solutions

Designed for versatility, the Magnet Drive Filter Unit accommodates varied tank capacities and dimensional requirements to match your specific application. It stands out as a reliable choice for manufacturers demanding precise control over chemical filtration and process integrity.

Durable and Chemical-Resistant Construction

Using Polypropylene, PVDF, or SS316 for the housing, this unit resists corrosion even when exposed to aggressive chemicals typically encountered in industrial processes. The high-quality materials assure extended service life and reduced maintenance needs in harsh conditions.

Advanced Pump Technology for Safety and Performance

The integrated magnetically driven centrifugal pump eliminates shaft seal leaks, minimizing the risk of chemical exposure and ensuring efficient, safe operation. This technology is ideal for environments where leak prevention and operational continuity are crucial.

FAQs of Magnet Drive Filter Unit:

Q: How is the Magnet Drive Filter Unit installed on site?

A: The Magnet Drive Filter Unit features a vertical floor-mounted installation, making it straightforward to set up in most industrial facilities. Installation requires a level surface and appropriate connections to process lines as per your specific layout and dimensional needs.Q: What types of filters are compatible with this filtration unit?

A: This unit supports both cartridge and bag filter types, allowing selection based on the desired filtration precision and the nature of the fluid being processed. These options facilitate effective removal of particulates in various industrial applications.Q: When is the optimal time to use a Magnet Drive Filter Unit?

A: The filter unit is most beneficial when continuous, reliable filtration is essential, such as during electroplating, chemical processing, or surface treatment operations. Its chemical resistance and robust construction make it suitable for ongoing, demanding processes.Q: Where can the Magnet Drive Filter Unit be utilized?

A: It is suitable for use in industries across India and globally that require high-performance chemical filtration, including manufacturing plants involved in electroplating, surface finishing, and chemical processing.Q: What is the process for maintaining the filter unit?

A: Routine maintenance involves inspecting the filter elements, replacing cartridges or bags as needed, and periodically checking the pump and housing for signs of wear. The use of corrosion-resistant materials simplifies maintenance over the units long operational life.Q: What are the key benefits of using this filtration equipment?

A: Users benefit from excellent chemical resistance, adaptability to various process needs, long service life, and reduced risk of chemical leaks. The customizable design and reliable operation contribute to lower maintenance costs and improved safety.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Electroplating Equipments Category

Electrical Immersion Heater Electroplating

Price 500 INR / Piece

Minimum Order Quantity : 10 Pieces

Dimension (L*W*H) : Variable, customizable as per requirements

Equipment Type : Other, Electrical Immersion Heater Electroplating

Grade Standard : Industrial Grade

Packaging Type : Robust Carton/ Wooden Box Packing

Electroplating Plant

Price 500000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Dimension (L*W*H) : 3000 mm x 1200 mm x 900 mm

Equipment Type : Other, Electroplating Plant

Grade Standard : Industrial Grade

Packaging Type : Standard Export Worthy Packaging

Electroplating Rectifier

Price 80000 INR / Piece

Minimum Order Quantity : 1 Piece

Dimension (L*W*H) : 900 x 900x 900 Millimeter (mm)

Equipment Type : Electroplating Machine

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS