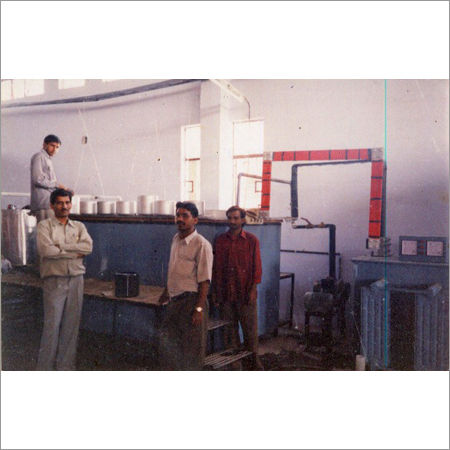

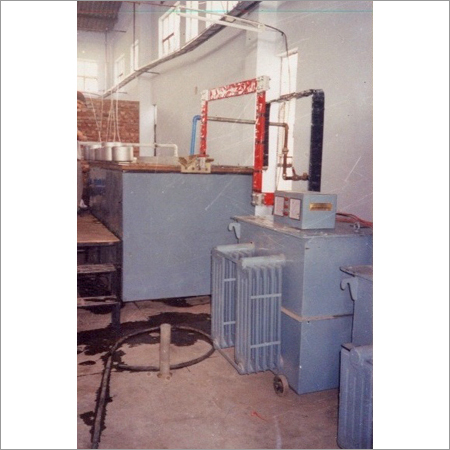

Aluminum Anodizing Plant

Price 100000 INR/ Unit

Aluminum Anodizing Plant Specification

- Product Type

- Aluminum Anodizing Plant

- Computerized

- Yes

- Automatic Grade

- Automatic

- CNC Or Not

- Not CNC

- Control System

- PLC Based Automated System

- Center Distance

- Customized as per requirement

- Dimension (L*W*H)

- Customizable (Typical: 15000 mm x 2500 mm x 3000 mm)

- Color

- Silver/Grey (Standard Industrial Finish)

About Aluminum Anodizing Plant

Ever since our inception, we have been involved in manufacturing and supplying an exceptional range of Aluminum Anodizing Plant. These plants are installed in aluminum profile extrusion, food can making, cookware and utensils industries for coating aluminum layer on different metals. Our veteran engineers design Aluminum Anodizing Plant by using premium quality materials and modern technology at our state of the art machining facility. We adhere to the parameters of the national and international quality standards to provide the clients with utmost satisfaction in terms of quality.

Features:

- Simple to operate

- Advance service life

- Zero maintenance

Superior Surface Finish Versatility

With options for matte, bright, satin, and color anodizing, our plant enables manufacturers to achieve tailored finishes for diverse applications, including decorative and protective coatings. The high-performance rectifier and precise temperature control ensure consistent results.

Advanced Automation and Control

Benefit from a PLC-based, user-friendly digital control panel, enabling accurate process management and reduced labor requirements. Integrated material handling and monitoring enhance operational safety and efficiency throughout production.

Environmental and Quality Assurance

Equipped with an integrated fume extraction and effluent treatment system, our anodizing plant adheres to international compliance standards (ISO 9001, CE) for worker safety and environmental stewardship, providing peace of mind for modern operations.

FAQs of Aluminum Anodizing Plant:

Q: How does the Aluminum Anodizing Plant ensure consistent surface finish quality?

A: The plant features precise digital rectifier monitoring, high-efficiency anodizing, and advanced PLC-based automated controls. These systems ensure consistency in temperature, voltage, and chemical dosing, resulting in uniform, repeatable matte, bright, satin, or colored finishes across batches.Q: What are the primary benefits of the integrated fume extraction and scrubber unit?

A: The integrated extraction and scrubber system safely removes hazardous fumes generated during anodizing, safeguarding operators and maintaining compliance with environmental and workplace standards. This provides clean air within the facility and supports responsible manufacturing practices.Q: When and where is this anodizing plant typically used?

A: The Aluminum Anodizing Plant is commonly installed in factories for architectural, automotive, aerospace, and industrial part finishing. Its customizable center distance and dimensions suit new or existing production lines requiring surface protection, durability, and decorative finishes.Q: What support does the manufacturer provide for installation and operation?

A: Comprehensive onsite installation and training services are provided, giving operators the knowledge to run and maintain the system efficiently. Post-installation support is available for troubleshooting, maintenance, and process optimization to ensure smooth operations.Q: How does the effluent treatment unit contribute to environmental compliance?

A: The effluent treatment unit processes wastewater and chemicals resulting from the anodizing operation, mitigating pollution risk and guaranteeing adherence to ISO 9001 and CE environmental standards. This helps facilities meet regulatory requirements and operate sustainably.Q: Is the control system easy to operate for technical staff?

A: Yes, the plant includes a user-friendly digital control panel integrated with PLC automation. This intuitive interface allows for easy process adjustments and monitoring, reducing operator error and ensuring efficient management of the anodizing process.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Plant Category

Electroplating Rectifiers

Price 26000 INR / Piece

Minimum Order Quantity : 1 Piece

Computerized : No

Material : Mild Steel Body

Center Distance : Customized as per application

Control System : Other, Thyristorised (SCR) Control System

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS