Electroplating Rectifiers

Price 26000 INR/ Piece

Electroplating Rectifiers Specification

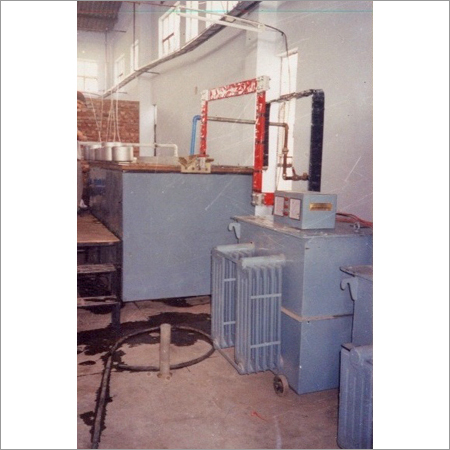

- Product Type

- Electroplating Rectifier

- Material

- Mild Steel Body

- Computerized

- No

- CNC Or Not

- No

- Control System

- Thyristorised (SCR) Control System

- Center Distance

- Customized as per application

- Power

- 5 kW to 100 kW

- Dimension (L*W*H)

- Varies as per model

- Capacity

- 50 Amps to 10,000 Amps

- Feature

- Low Power Consumption, High Efficiency, Heavy Duty Construction

- Color

- Blue & White

Electroplating Rectifiers Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 10 Pieces Per Week

- Delivery Time

- 1 Week

About Electroplating Rectifiers

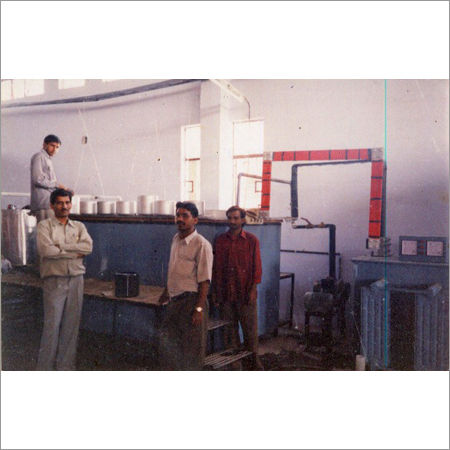

We have marked a special niche in the global market by manufacturing and supplying a qualitative assortment of Processing Machinery Plant. These plants are used in metal processing and automotive industries for cutting, drilling and finishing of the metal objects. We employ advance machines and quality approved materials to manufacture Processing Machinery Plant, in accordance with industry set norms and standards. In addition, our clients can avail these plants from us at a pocket friendly price.

Features:

- User friendly operation

- Optimum performance

- Less in maintenance

Advanced Control and Protection Systems

These rectifiers incorporate a thyristorized (SCR) control system, ensuring precise output regulation of less than 1%. Multiple protection features guard against overload, short circuit, and over temperature, safeguarding both the equipment and production process. This advanced control system extends product lifespan and minimizes unscheduled downtime.

Customizable Designs and Applications

With flexible options such as adjustable output current, digital displays, and a variety of cooling mechanisms, each rectifier can be tailored to unique client specifications. Their modular design supports easy floor-mounted installation and allows for customization in center distances and dimensions, fitting a wide array of applications in metal finishing and surface treatment industries.

Efficient and Durable Construction

Manufactured with a heavy-duty mild steel body finished in blue and white, these rectifiers are built for high efficiency and low power consumption. Their robust construction and reliable technology make them suitable for continuous use in demanding industrial environments, ensuring dependable performance and consistent results.

FAQs of Electroplating Rectifiers:

Q: How do I choose between single-phase and three-phase electroplating rectifiers for my application?

A: The selection depends on your process scale and power requirements. Single-phase rectifiers suit smaller applications with lower current demands, while three-phase units are ideal for larger installations needing higher capacities, such as industrial-scale electroplating or anodizing.Q: What cooling methods are available, and when should I use air, oil, or water cooling for rectifiers?

A: Air cooling is suitable for moderate-duty operations in ambient environments. Oil or water cooling is recommended for heavier applications or areas with higher temperatures, as they provide superior heat dissipation and ensure optimal performance under continuous load.Q: Where can these electroplating rectifiers be installed?

A: Designed as floor-mounted units, rectifiers are ideal for installation in industrial workshops, manufacturing facilities, and service centers specializing in metal finishing, electroforming, or plating processes.Q: What is the process for regulating output current and voltage in these rectifiers?

A: Output current and voltage are adjustable using the thyristorized (SCR) control system, enabling precise regulation as per specific process requirements. This advanced technology ensures stable operation and uniform plating results.Q: What benefits does digital display provide for monitoring rectifier operation?

A: Digital volt and amp meters offer real-time, accurate readings, making it easy for operators to monitor and adjust parameters, thus improving process control and helping maintain consistent quality in electroplating and metal finishing tasks.Q: What protection features safeguard these rectifiers during operation?

A: Integrated overload, short circuit, and over temperature protection systems automatically prevent damage and downtime, protecting both the rectifier and connected equipment from electrical faults.Q: Are these rectifiers available in customized sizes and capacities?

A: Yes, models are available with customizable dimensions, center distances, and output capacities ranging from 50 to 10,000 Amps, ensuring a perfect fit for varied process requirements and space constraints.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Plant Category

Aluminum Anodizing Plant

CNC Or Not : Other, Not CNC

Product Type : Other, Aluminum Anodizing Plant

Computerized : Yes

Control System : Other, PLC Based Automated System

Dimension (L*W*H) : Customizable (Typical: 15000 mm x 2500 mm x 3000 mm)

Color : Other, Silver/Grey (Standard Industrial Finish)

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS