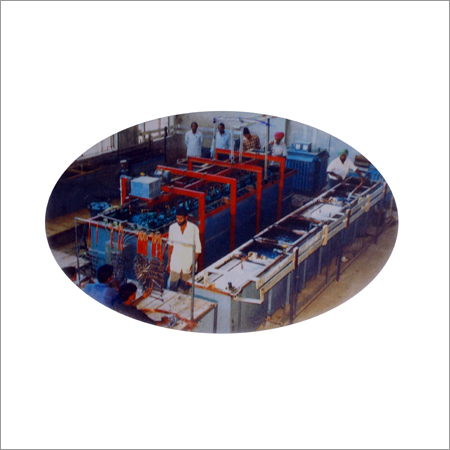

Automatic Electroplating Line

Price 37000 INR/ Unit

Automatic Electroplating Line Specification

- Grade Standard

- Industrial Grade

- Packaging Type

- Standard Export Packing

- Chemical Name

- Electrolytic Plating Chemicals (Nickel, Chrome, Zinc, Copper, etc.)

- Tank Capacity

- 200 L to 5000 L (customizable)

- Equipment Type

- Automatic Electroplating Line

- Dimension (L*W*H)

- Customized as per client requirements

- Voltage

- 380V/415V, 3 Phase, 50/60Hz

Automatic Electroplating Line Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 1000 Units Per Week

- Delivery Time

- 1 Week

About Automatic Electroplating Line

With our complete know how of the domain, we have emerged as a reliable manufacturer and supplier of Automatic Electroplating Line. We made these by using best quality materials at our state of the art machining facility, in-sync with the globally laid quality standards. Our Automatic Electroplating Line is used for nickel, zinc, copper, tin and lead electroplating process on various metal objects in tool, hardware and automotive industries. Our clients can avail these machines from us at a reasonable price.

Features of Automatic Electroplating Line:

- Energy efficient

- Smooth operation

- Durable service life

Further Details of Automatic Electroplating Line:

We are designing Semiautomatic Electroplating Lines for

- Bi-cycle component Industry

- Industrial Hardware Industry

Hoe Appliances

FAQs of Automatic Electroplating Line:

What is automation of electroplating process?

Plating robotization is basically the most common way of utilizing specific apparatus and gear to carry out the different methodology in the electroplating application. Plating computerization requires less human intercession than conventional manual plating processes.

Which electroplating is ideal?

Gold is exceptionally conductive, safeguards against high intensity, forestalls consumption and is impervious to wear. For stylish applications, for example, gems, gold gives a splendid and appealing completion. Gold is many times the most ideal decision for electroplating of semiconductors, circuits and connectors.

What is the most grounded metal for electroplating?

In its regular state, it is the hardest metal there is. Ideal for electroplating.

Precision Automation for Metal Finishing

Experience seamless metal surface finishing with our precision-engineered automatic electroplating line. Designed to achieve consistent and high-quality plating results, this automated system integrates PLC/HMI controls, ensuring operational reliability and minimal manual intervention. With customization options in material and chemical compatibility, you can efficiently manage processes for a wide range of applications.

Customizable To Meet Your Needs

Each electroplating line is tailored to your specific requirements, from tank capacity and dimensional layout to surface treatment processes. Materials of construction are selected based on chemical and operational demands, while features like fume extraction and overload protection enhance overall safety. Custom panel integration and process settings offer unparalleled versatility in operation.

Expert Support and Installation

Benefit from our turnkey solutions, including on-site installation and commissioning, provided by experienced technicians. Standard export packaging safeguards the equipment during transit, and our responsive service ensures your automatic electroplating line is installed and operational without delay. Ongoing support is just a call away for all customers.

FAQs of Automatic Electroplating Line:

Q: How does the automatic electroplating line improve production efficiency?

A: The automatic electroplating line streamlines the plating process through fully automated PLC/HMI controls, reducing the need for manual labor and minimizing errors. This allows for precise repetition of processes, boosting productivity up to 10,000 pieces per day, depending on component type and plating process.Q: What materials and chemicals are compatible with this electroplating line?

A: Our system is constructed from Stainless Steel, PP, or PVC, selected according to the chemicals used and application requirements. It supports electrolytic plating chemicals such as nickel, chrome, zinc, and copper, accommodating a variety of custom plating needs.Q: When is installation and commissioning offered for this equipment?

A: Installation and commissioning support is available as part of our service offering. Experienced technicians oversee the entire setup process to ensure optimal functionality and smooth operation upon delivery.Q: Where can this automated electroplating line be installed?

A: The system is designed for versatile installation across industrial settingsincluding manufacturing facilities, workshops, and large-scale production plants. The dimensions of the line are customizable to fit your facilitys layout.Q: What is the process for customizing the tank capacity and control system?

A: Tank capacity and control systems are tailored to your specific requirements during the consultation phase. We offer tanks from 200 to 5,000 liters, and you can choose between PLC or HMI control systems depending on operational needs.Q: How are safety and environmental concerns addressed in this electroplating line?

A: Safety is a priority, with features such as emergency stop mechanisms, overload protection, and an efficient fume extraction system to control hazardous emissions and enhance workplace safety.Q: What are the benefits of choosing an industrial-grade, automatic electroplating line from your company?

A: Selecting our industrial-grade line ensures you receive robust, customizable equipment backed by expert support and installation. Automation increases production consistency, safety features reduce operational risk, and advanced controls support a wide range of metal finishing applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS