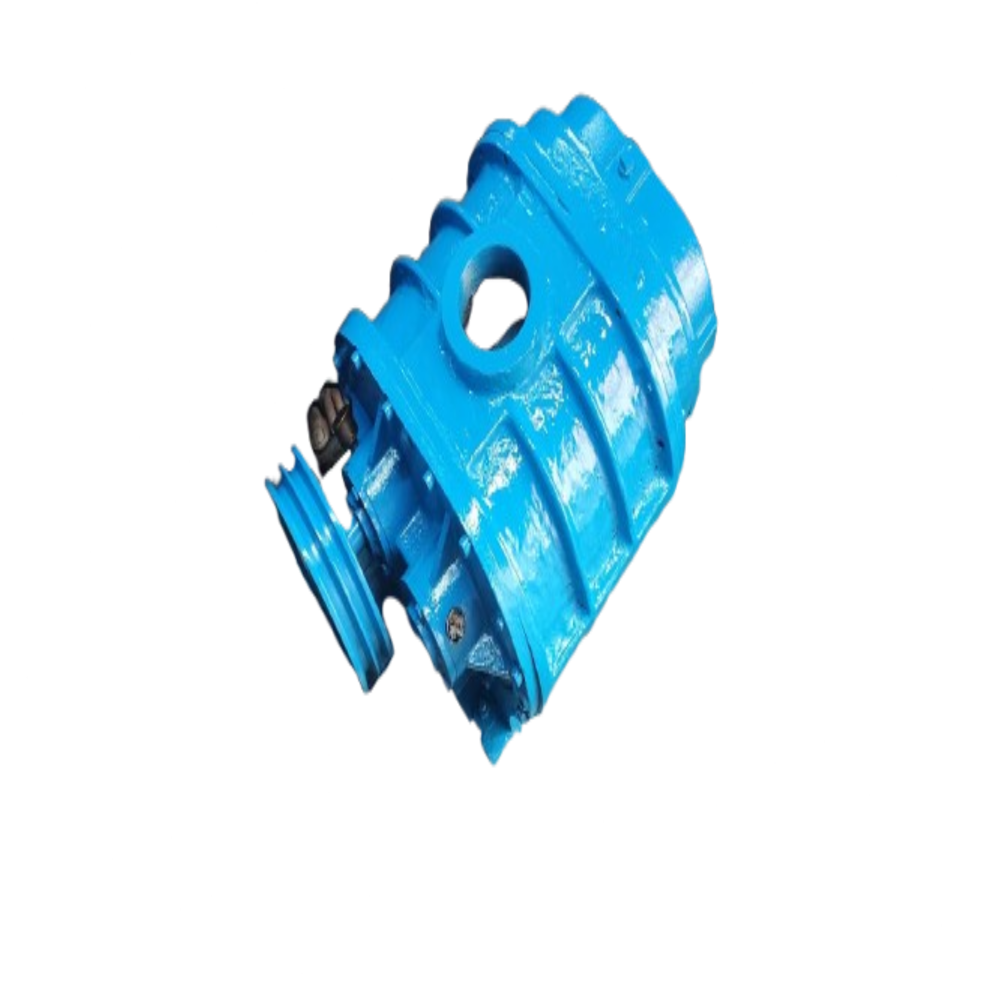

Electroplating Plant

Price 500000.00 INR/ Unit

Electroplating Plant Specification

- Concentration

- As per process requirement

- Temperature Range

- Ambient to 60C

- Grade Standard

- Industrial Grade

- Chemical Name

- Nickel Sulphate, Copper Sulphate, Zinc Sulphate, Chrome

- Packaging Type

- Standard Export Worthy Packaging

- Equipment Type

- Electroplating Plant

- Dimension (L*W*H)

- 3000 mm x 1200 mm x 900 mm

- Voltage

- 220 V

- Application Area

- Electroplating of metals such as Zinc, Nickel, Chrome, Copper

- Power Source

- Electric

- Surface Treatment

- Galvanized / Chemical Coated

- Material of Construction

- PP/FRP/MS/SS

- Corrosion Resistance

- Yes

- Control Panel

- Digital / Manual control available

- Number of Tanks

- Custom as per plant design

- Heater Type

- Immersion Heater

About Electroplating Plant

As one of India's leading manufacturers, we are committed to offer a technically advanced range of Electroplating Plant. These plants are very effective in carrying out plating process like nickel plating, zinc plating, copper plating, tin plating and lead plating. Made from top notch materials at our state of the art machining facility, our Electroplating Plant is largely demanded in automotive, engineering, and electrical industries. Furthermore, our clients have the advantage to customize these plants as per their needs.

Features:

- Advance service life

- Simple to operate

- Less power consumption

Customizable Engineering for Precision Electroplating

Every electroplating plant is tailored to specific industrial needs, offering customization in tank numbers, materials of construction, and control systems. Whether for zinc, nickel, chrome, or copper plating, our solutions ensure consistent, high-quality results. The integration of immersion heaters and versatile control panels assures precise process management and operational flexibility.

Durable Construction and Corrosion Resistance

Manufactured from PP, FRP, MS, or SS, the plant assures long-term durability, even under harsh chemical conditions. Corrosion resistance is a key attribute, securing both equipment longevity and process efficiency. This steadfast construction supports rigorous, continuous operations required by demanding electroplating processes.

FAQs of Electroplating Plant:

Q: How does the electroplating process work in your plant?

A: Our plant uses a combination of custom-built tanks, immersion heaters, and precise digital or manual controls to conduct the electroplating process. Metals such as zinc, nickel, chrome, or copper are deposited onto the components surface using electrical current and appropriate chemical solutions at controlled temperatures.Q: What benefits does corrosion resistance provide in your construction materials?

A: Constructing tanks from PP, FRP, MS, or SS offers excellent corrosion resistance, which prolongs equipment lifespan, reduces maintenance, and ensures stable plating quality. This is especially vital given the plants exposure to aggressive chemicals involved in the electroplating process.Q: When should the concentration and temperature be adjusted during electroplating?

A: Adjustments to chemical concentration and operating temperature are made according to the specific metal being plated and the process requirements. Plant operation can range from ambient to 60C and concentrations are maintained in alignment with industrial electroplating protocols for nickel, copper, zinc, or chrome.Q: Where can your electroplating plant be installed?

A: Our electroplating plants are suitable for various industrial settings across India and internationally. Each unit is delivered in standard export-worthy packaging, ensuring safe transit and installation at the clients facility, whether for manufacturing hubs or specialized service centers.Q: What maintenance is required for optimal operation?

A: Routine inspections to ensure immersion heaters, control panels, and tanks remain in prime condition are essential. Proper cleaning, timely chemical replenishment, and checks for wear, particularly on corrosion-resistant components, help maintain consistent plant performance.Q: How does digital versus manual control impact usage?

A: Digital control panels provide automated, precise process management, enabling easier monitoring and adjustments. Manual controls, on the other hand, offer direct operation for plant managers who prefer hands-on oversight. Both options are designed to optimize plating uniformity and process safety.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Electroplating Equipments Category

Electrical Immersion Heater Electroplating

Price 500 INR / Piece

Minimum Order Quantity : 10 Pieces

Dimension (L*W*H) : Variable, customizable as per requirements

Equipment Type : Other, Electrical Immersion Heater Electroplating

Shelf Life : Up to 5 years (if properly maintained and stored)

Tank Capacity : Variable, suitable for standard and custom tanks

Magnet Drive Filter Unit

Price 15000 / Unit

Minimum Order Quantity : 1 Unit

Dimension (L*W*H) : As per requirement

Equipment Type : Other, Magnet Drive Filter Unit

Shelf Life : Long Life

Tank Capacity : Varies (Customizable)

Electroplating Rectifier

Price 80000 INR / Piece

Minimum Order Quantity : 1 Piece

Dimension (L*W*H) : 900 x 900x 900 Millimeter (mm)

Equipment Type : Electroplating Machine

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS